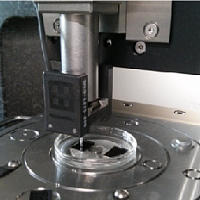

Hysitron TI 950

The TI 950 combines Hysitron’s patented three plate capacitive transducer* technology with state-of-the-art control technology to achieve unmatched performance in nanomechanical characterization. The system features a sub 30 nN force noise floor, ultra-fast feedback control, user-definable data acquisition rates up to 30 kHz, the widest range of nanomechanical testing techniques, and the ability to test with various Hysitron heads seamlessly. The superior staging system on the TI 950, along with the in-situ Scanning Probe Microscopy (SPM) imaging capability, provides unparalleled precision in test-placement accuracy and data repeatability.

Publications

RONOH, K.; NOVOTNÝ, J.; MRŇA, L.; KNÁPEK, A.; SOBOLA, D., 2024: Analysis of processing efficiency, surface, and bulk chemistry, and nanomechanical properties of the Monel® alloy 400 after ultrashort pulsed laser ablation. MATERIALS RESEARCH EXPRESS 11 (1), doi: 10.1088/2053-1591/ad184b (DEKTAK, MIRA-STAN, KRATOS-XPS, NANOINDENTER)

Rogl, G.; Bursikova, V.; Yubuta, K.; Murayama, H.; Sato, K.; Yamamoto, W.; Yasuhara, A.; Rogl, P., 2024: In-situ observation of temperature dependent microstructural changes in HPT-produced p-type skutterudites. JOURNAL OF ALLOYS AND COMPOUNDS 977, doi: 10.1016/j.jallcom.2024.173431 (NANOINDENTER)

Zeman, P.; Haviar, S.; Houška, J.; Thakur, D.; Bondarev, A.; Červená, M.; Medlín, R.; Čerstvý, R., 2024: Self-formation of dual-phase nanocomposite Zr–Cu–N coatings based on nanocrystalline ZrN and glassy ZrCu. MATERIALS & DESIGN 245, doi: 10.1016/j.matdes.2024.113278 (TITAN, HELIOS, NANOINDENTER)

Kuptsov, K. A.; Antonyuk, M. N.; Sheveyko, A. N.; Bondarev, A. V.; Shtansky, D. V., 2023: Influence of TiC Addition on Corrosion and Tribocorrosion Resistance of Cr2Ti-NiAl Electrospark Coatings. COATINGS 13 (2), doi: 10.3390/coatings13020469 (TITAN, HELIOS, NANOINDENTER)

Sharifahmadian, O.; Pakseresht, A.; Mirzaei, S.; Eliáš, M.; Galusek, D., 2023: Mechanically robust hydrophobic fluorine-doped diamond-like carbon film on glass substrate. DIAMOND AND RELATED MATERIALS 138, doi: 10.1016/j.diamond.2023.110252 (KRATOS-XPS, VERIOS, NANOINDENTER, RIE-FLUORINE)

Plichta, T.; Zahradnicek, R.; Cech, V., 2022: Surface topography affects the nanoindentation data. THIN SOLID FILMS 745, doi: 10.1016/j.tsf.2022.139105 (HELIOS, NANOINDENTER)

Bodner, S. C.; Hlushko, K.; Van De Vorst, L. T.G.; Meindlhumer, M.; Todt, J.; Nielsen, M. A.; Hooijmans, J. W.; Saurwalt, J. J.; Mirzaei, S.; Keckes, J., 2022: Graded Inconel-stainless steel multi-material structure by inter- and intralayer variation of metal alloys. JOURNAL OF MATERIALS RESEARCH AND TECHNOLOGY 21, p. 4846 - 4859, doi: 10.1016/j.jmrt.2022.11.064 (NANOINDENTER)

Bondarev, A. V.; Antonyuk, M. N.; Kiryukhantsev-Korneev, Ph V.; Polcar, T.; Shtansky, D. V., 2021: Insight into high temperature performance of magnetron sputtered Si-Ta-C-(N) coatings with an ion-implanted interlayer. APPLIED SURFACE SCIENCE 541, doi: 10.1016/j.apsusc.2020.148526 (VERIOS, HELIOS, KRATOS-XPS, NANOINDENTER)

SMOLIK, J.; KNOTEK, P.; SCHWARZ, J.; ČERNOŠKOVÁ, E.; KUTÁLEK, P.; KRÁLOVÁ, V.; TICHÝ, L., 2021: Laser direct writing into PbO-Ga2O3 glassy system: Parameters influencing microlenses formation. APPLIED SURFACE SCIENCE 540, p. 148368-1 - 9, doi: 10.1016/j.apsusc.2020.148368 (NANOINDENTER)

Mouralova K., Benes L., Bednar J., Zahradnicek R., Prokes T., Matousek R., Hrabec P., Fiserova Z., Otoupalik J., 2019: Using a DoE for a comprehensive analysis of the surface quality and cutting speed in WED-machined hadfield steel. JOURNAL OF MECHANICAL SCIENCE AND TECHNOLOGY 33 (5), p. 2371 - 2386, doi: 10.1007/s12206-019-0437-4 (LYRA, TITAN, NANOINDENTER, HELIOS)

Yavas, H.; Fraile, A.; Huminiuc, T.; Sen, H. S.; Frutos, E.; Polcar, T., 2019: Deformation-Controlled Design of Metallic Nanocomposites. ACS APPLIED MATERIALS AND INTERFACES 11 (49), p. 46296 - 46302, doi: 10.1021/acsami.9b12235 (NANOINDENTER, TITAN, HELIOS)

Mouralova, K.; Benes, L.; Zahradnicek, R.; Bednar, J.; Hrabec, P.; Prokes, T.; Matousek, R.; Fiala, Z., 2018: Quality of surface and subsurface layers after WEDM aluminum alloy 7475-T7351 including analysis of TEM lamella. INTERNATIONAL JOURNAL OF ADVANCED MANUFACTURING TECHNOLOGY 99 (9-12), p. 2309 - 2326, doi: 10.1007/s00170-018-2626-1 (LYRA, ICON-SPM, HELIOS, TITAN, NANOINDENTER)